Menu

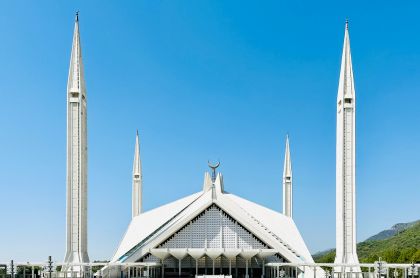

PTFE fiberglass membranes can be installed in climates ranging from the frigid Arctic to scorching desert heat with an expected project life exceeding 30 years. PTFE Fiberglass coating is chemically inert, capable of withstanding temperatures from – 100F to +450F. The Low-surface free energy of the material creates a surface that is readily cleaned by rainwater. It is also completely immune to UV degradation. This unique combination of inertness, thermal stability, and surface properties make Birdair’s PTFE-Coated fabric membrane ideal for the project requiring superior weather and fire resistance.

PTFE Fiberglass structure has been constructed around the world with the acceptance by UAE, British, French, Italian, Japanese, and German National Standards as well as guidelines set by the American Society for Testing and Materials (ASTM). PTFE Fiber Glass membranes can be installed in climates ranging from grid arctic to scorching desert heat with an expected project life exceeding 30 years.

During Scientific tests of its solar properties, it was discovered that PTFE Fiberglass membranes reflect as much as 73% of the Sun’s Energy while holding just even percent on its exterior surface. PTFE fiberglass is additionally Energy Star and Cool Roof Rating Council certified.

Certain Grades of PTFE fiberglass can absorb 14% of the sun’s energy while allowing 13% of natural daylight and 7% of re-radiated energy to transmit through. PTFE’s Fiberglass yarns maintain an ultimate tensile strength of 500,000 PSI and a modulus of elasticity of 10.5 x 106 PSI compared to steel which offers 40,000 PSI and 29 x 106 PSI respectively.

Under normal conditions, the fabric behaves elastically and does not undergo significant stress relaxation on creep. The Woven fiberglass gives the PTFE fiberglass membrane with maximum flexibility. The fibers are drawn from hot melt glass through platinum dies into continuous filaments and are then twisted and pied into yarn bundles. The yarns are woven into a wide structure are woven into a wide structural fabric which is then coated with PTFE fiberglass to complete the process.

TiO2-coated PTFE is a type of fiberglass that is safe and flame-resistant. It uses titanium dioxide (TiO2) to create a protective layer that helps clean the air by breaking down pollutants and odors. This material is popular with designers and architects in Asia and is starting to be used in North America. The self-cleaning property of TiO2 means that it uses sunlight, oxygen, and moisture to convert pollutants into safe gases, reducing the need for cleaning and maintenance. The remaining residues are easily washed away by rain. TiO2-coated PTFE is a modern and eco-friendly material suitable for various structures and roofing systems. It comes in different grades depending on the level of light transmission needed and is effective in urban and industrial areas where pollutants like nitrogen and sulfur oxides are common.

When designing structures, acoustical considerations are essential. Key areas of focus include controlling external noise and ensuring internal sound quality. Different issues are assessed to maintain appropriate noise levels, with specific considerations for various environments.

Main Points:

Noise Control: It is crucial to prevent external noise from entering the building and to manage internal sound to avoid excessive echo and vibration.

Absorption and Clarity: Acoustical materials should absorb sound to improve clarity, especially in places where clear communication is vital. Solid materials alone are not sufficient for good acoustics.

Challenging Environments: Large spaces like arenas, maritime centers, and stadiums require special attention to acoustics. Noise criteria (NC) levels guide acceptable noise levels in different environments, from NC-20 in quiet halls to NC-50 in noisy sports facilities.

PTFE-Coated Acoustical Membranes: These membranes are effective in controlling sound and providing good acoustics. They help reduce unwanted noise and improve sound quality within the space.

Head office

AKAA TENT Inc 1590 Reem Road Pennington New Jersey 08534

AL Khayam Al Arabiah Tents & Shade TR LTD England and Wales

Empire Marquee Office no. 1113, Eden heights building, Jail Road

© 2008 – 2024 Al Khayam Al Arabiah Tents & Sheds TRD. LLC in Sharjah, Dubai, Abu Dhabi, UAE | All rights reserved.